How Cutting-edge Steel Products are Driving India’s Automotive Industry

Steel is one of the most widely used materials in the automotive industry today, contributing up to 65% of the total raw material content in the average Indian vehicles. As a material of strength, it gives quality in terms of safety and durability to vehicles at comparatively lower costs as compared to other materials.

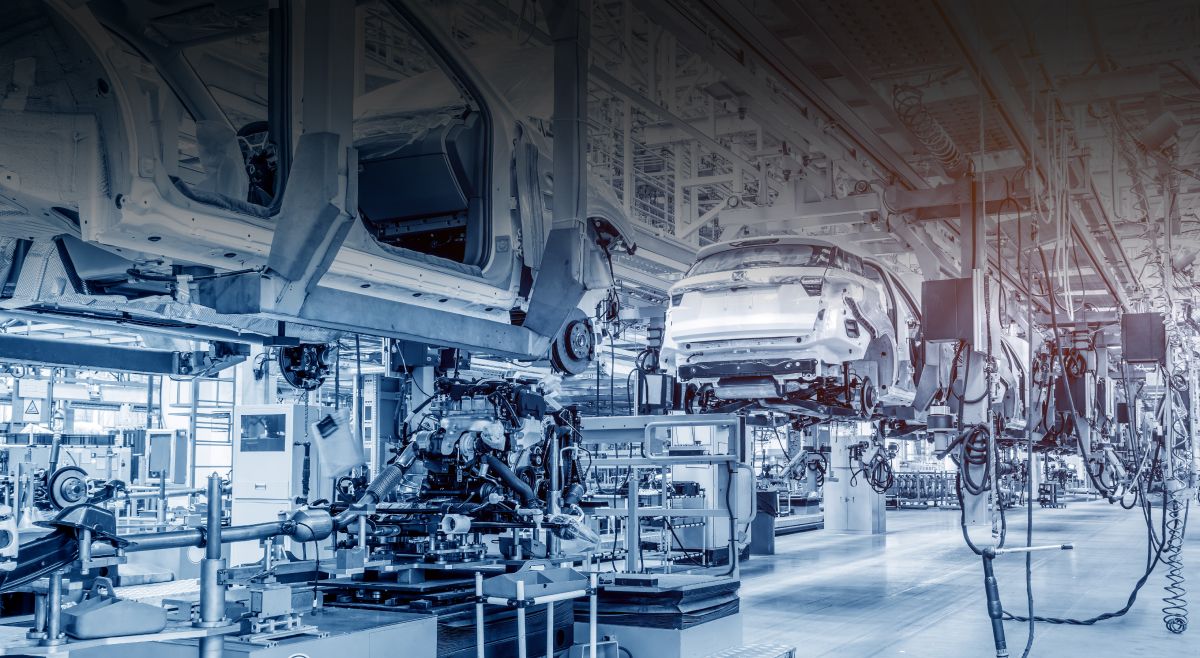

With urbanisation, there has been an increase in the production of automobiles. It goes without saying that, as a vital component of safe and efficient mobility on the road, the steel must be of premium quality and should be able to bear the constant wear and tear as vehicles plying on the road get exposed to extreme conditions.

Why Steel?

Steel is well-known for its strength, durability and high endurance abilities. Owing to its superior tensile strength and high durability aspect, steel is used in manufacturing car bodies to ensure safety and longevity of the vehicle. Put simply, we can say that the presence of steel and the steel business in India has an influential impact on the encompassing automotive industry.

How Steel Is Used in the Automotive Industry?

Besides the vital frame of the car and bike, almost every other part of a vehicle is somewhat made of steel. They help withstand extreme pressure generated by the vehicle. Also, private and public transportation industry depends heavily on the supply of steel. Bus bodies are made with high-quality steel as it adds weight and strength to the bus as well as has the ability to withstand extreme on-road pressure.

The propeller shafts in vehicles are mostly made up of steel because you need materials that exhibit high torsional rigidity and can take a lot of wear and tear. From crankshaft to exhaust tubes in automobiles, all crucial parts of an automobile are made of steel. Whether it’s a car, bike or bus, seat frames are manufactured with steel. It is so because the steel ensures the seats are created in the desired shape, size, comfort and strength.

Over the last few decades, JSW Steel has been the preferred steel product supplier in India for all major automotive manufacturers and ancillaries in the country. The kind of steel manufactured here is strong and of the finest quality fulfilling the desirable standards of the vehicle in question. It exhibits high tensile strength and ability to withstand tremendous pressure and force.

The Indian Automotive Industry has made great strides over the past two decades and has emerged as one of the fastest growing markets in the world. It became the 4th largest in the world in 2017 and the 7th largest manufacturer of commercial vehicles in the same year. India is also a prominent auto exporter with strong export growth expectations for the near future.

Additionally, several initiatives by the Government of India and major automobile players in the Indian market are expected to make the country a world leader in the two-wheeler and four-wheeler market by 2020. In view of the above, JSW has heavily invested in new facilities, capabilities and infrastructure to take the lead in becoming a cutting-edge steel product manufacturer for the automotive industry and propelling India to a position of leadership in the global automotive industry.