Energy

We at JSW believe that energy saved is energy produced and thus we aim to conserve resources and energy by adopting the best available practices of the industry. As the exhaustion of fossil fuels, which supply three-quarters of this energy, is not far off, JSW is striving towards optimizing the energy required for its operations and also building infrastructure to produce green electricity as a part of its energy portfolio. Through this, we also aim to contribute to UNDP’s Sustainable Development Goals.

SDG Mapping of JSW Steel’s Initiatives & Projects

SDG 12: Responsible Consumption and Production

- JSW Steel has implemented ISO 50001 across all its manufacturing locations, to promote energy management best practices.

- Sustainable management and efficient use of energy is achieved at JSW through targets linked to specific energy consumption (SEC) targets set in PAT cycles

- JSW Steel adopted state-of-the-art Energy Management Centre equipped with a supervisory control and data acquisition (SCADA) system

-

At JSW Steel Coated Products Ltd, we flagged off our first ever electric vehicle (EV) for material transfer in line with our objective to achieve carbon neutrality by 2030.

-

Vijayanagar Works took the following initiatives for energy conservation in FY22:

- Installation of 80TPH coal mill to increase the Pulverised Coal Injection (PCI) rate and to reduce the total fuel rate resulting in fuel savings – Coke rate 3.8 kg/thm

- Installation of CPP4 AOH condenser tube and high energy drains, improving energy efficiency

- Installation of CPP3 BFP RC valve actuator replacement BFP 3B, improving energy efficiency

- Cleaning of CPP3 condenser tube, resulting in energy savings of 19529 Gcal/Year

-

Dolvi Works took the following initiatives for energy conservation in FY22:

- Commissioned Coke Dry Quenching System (CDQ) Boiler 1, 2 & 3 in COP#1 & 2, resulting in reduction in steam generation from fuel-fired boiler and decrease in coke moisture leading to lesser coke rate of brownfield (BF), thus resulting in decrease in energy and carbon emissions

- Commissioning of Dry Gas Cleaning Plant (GCP) in BF#2, leading to higher power generation from Top Pressure Recovery Turbine (TRT), and 40% increase in power generation from TRT

- Increase in PCI in Blast Furnace up to 190 kg/thm, leading to reduction in overall solid fuel rate in BF, leading to decrease in energy and CO2 emissions

- Commissioning of LD convertor waste heat recovery boiler, resulting in waste heat recovery steam generation to the tune of 45 TPH, resulting in less requirement of fuel for steam generation

- Model-based air fuel ratio optimisation at BF Boiler to reduce Specific coke oven gas (COG) consumption, resulting in reduction in COG consumption per tonne of steam from 165 Nm3/t to 152 Nm3/t

- Insulation repair and replacement of steam traps throughout steam network, leading to reduction in steam loss to the tune of 1.5 TPH

- Maximising COG consumption in Sponge Iron Plant and conversion of Caster from natural gas (NG) to COG, resulting in replacement of purchased fuel (NG) by in-house generated COG

-

Salem Works took the following initiatives for energy conservation in FY22:

- Reducing TNEB import power during STG#2 Shutdown - power generation increased by 8.245 MW and has reached 59.9 MW

- Enhancing bf gas boiler steam generation in CPP2 - steam generation enhanced in BF gas boiler in CPP2 from 32 TPH to 34 TPH

SDG 9: Industry, Innovation and Infrastructure

- JSW has continuously invested in upgradation of infrastructure and retrofitting of existing plants to increase resource-use efficiency. Some of the latest technological enhancements include,

- Heat recovery from waste gases - JSW Vijaynagar commissioned 150 TPH Boiler for power augmentation along with 45.13 TPH of steam generation through a sinter cooler waste heat recovery boiler. These boilers are zero coal-fired boilers, 100% byproduct gas firing for process steam generation.

- At Dolvi, revamping of CPP turbine, identification and arresting of leakages resulted in the reduction of gaseous heat rate from 2641 Kcal/nm3 in FY 2017-18 to 2400 Kcal/ nm3. Fuel conversion of HSM Boiler & BF Cast house from NG to COG leading to NG saving of 672 KSm3.

- JSW aims at greater adoption of clean and environmentally sound technologies and industrial processes to attain energy security. JSW commissioned various such technologies like,

- Installation of BF gas holder – The aim of this project is to reduce the BF gas flare with 80,000 nm3/hour savings in turn of 67.63 Kg-CO2e/tonne of Crude Steel

- Coke Dry Quenching (CDQ) – JSW Steel is opting for CDQ in all its upcoming projects along with upgradation of existing units. Dry quenching of the coke instead of wet quenching can be used to recover sensible heat that would otherwise be lost from the coke while reducing dust. The steam recovery rate with this equipment is about 0.55 GJ/tonne coke. It is also known that dry quenching reduces the amount of coke consumption in the blast furnace thus providing an added benefit of resource conservation.

- Utilization of waste gas for power generation– JSW Steel utilizes 96% of its waste gases. Salem Works recorded its highest ever power generation in 2018-19 at 36.51 MW.

- Implementation of online air fuel ratio logic at CPP of Dolvi Works resulted in a reduction in CPP gaseous heat rate by 10.6%.

- Optimisation of Air Fuel ratio in BF Hot Blast stoves through digitalisation initiative has reduced the BF gas consumption, which resulted in savings of 6741 Gcals in FY 2018-19.

SDG7: Affordable and clean energy

- JSW Steel targets to increase the share of renewable energy consumption for steel making processes in the coming years.

- In Vijayanagar 13.3% of the total power consumption requirement of the blast furnace is fulfilled by the non-conventional power source of Top recovery turbine which generates about 18.3 MW. Also with 30% Increase in by-product gas supply YoY to power plants resulted in a coal saving of 21TPH in FY19.

- Dolvi Works initiated the usage of Coke Oven Gas in place of Natural Gas (NG) in FY 2018-19 at Direct Reduced Iron (DRI), Tunnel Furnace, Bar Mill, and SMS ladle pre-heater. Fuel conversion of HSM Boiler and BF Cast house from NG to COG lead to NG saving of 672 KSm3.

Automated Solar Power Plant at Vijayanagar -

JSW Steel has started utilising solar power with the commissioning of the 225 MW Renewable Solar Power Plant at Vijayanagar (by JSW Renewable Energy Vijayanagar Limited), resulting in reduction of steam coal consumption.

The solar plant is situated at Thimalapura village, Bellary district, approximately 20 km from the JSW Steel Plant of Vijayanagar. This has enabled us to supply 400 KV through a dedicated transmission corridor.

The plant at Thimalapura village is one of the largest captive solar power plants installed to supply power to any steel manufacturing unit in the country.

The plant is well automated with the use of the Supervisory Control and Data Acquisition (SCADA) system and provides access to the power generated with control across multiple locations.

The plant was set up in a safe manner, in compliance with all EHS norms of the JSW Group without any Loss Time Injury and also helped avoid emissions with the usage of 45 MW in steel operations.

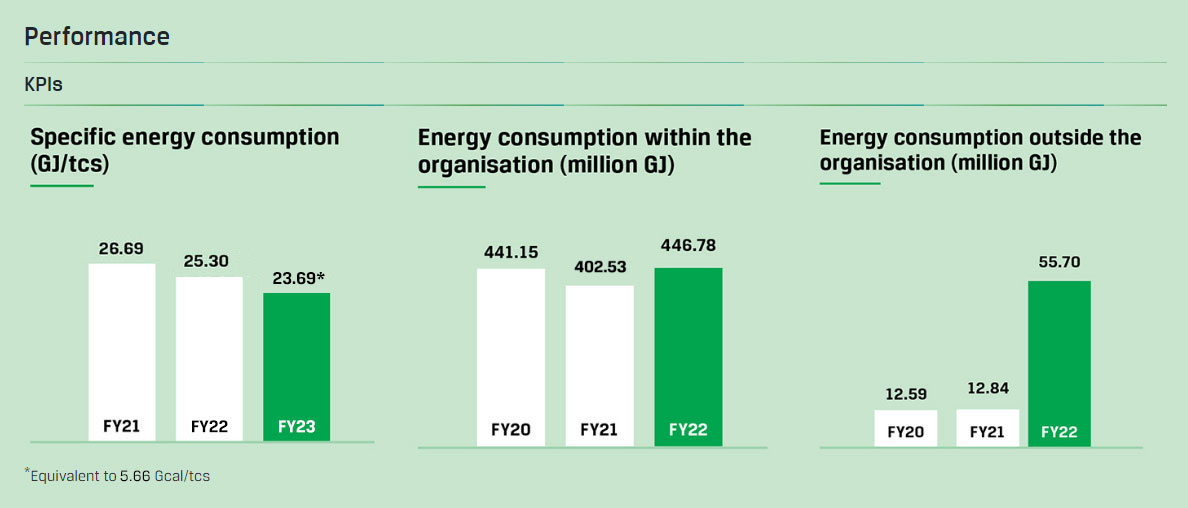

Energy Consumption Trend of JSW Steel

Through various energy conservation efforts, the specific energy consumption of JSW Steel has improved by 5.18% in FY19 compared to FY18

JSW Steel regularly discloses its sustainability performance and initiatives in its integrated report. These reports are available here