Performance by Capitals

Manufactured Capitals

Manufactured capital is the Company’s tangible and intangible infrastructure used for value creation through business activities. It encompasses power generation, transmission and trading capacities, mining assets and equipment manufacturing facilities. Manufacturing capital is the backbone of our Company. It supports production, development and innovation, and assures investment for future growth. Today, JSW Energy is a leading, full-spectrum, integrated power company, with presence across the power sector value chain. Our Company believes in the efficient utilisation of all available resources throughout its value chain, which enables it to be competitive and responsive to the market dynamics and environmental needs, in turn maximising the returns for its stakeholders.

We have an operational generation capacity of 4,541 MW, which comprises 3,140 MW of thermal power, 1,391 MW of hydro power (including 91 MW capacity in approval phase) and 10 MW solar power capacities, which are spread across the states of Karnataka, Maharashtra, Rajasthan, Himachal Pradesh, West Bengal and Andhra Pradesh. Additionally, we have two 400 kV transmission lines in Maharashtra in a joint venture with Maharashtra State Electricity Transmission Company Ltd. (MSETCL) and a 9 MTPA combined capacity of lignite mines in Rajasthan in a joint venture with Rajasthan State Mines and Minerals Limited (RSMML). We also have a joint venture with Toshiba Corporation for manufacturing supercritical steam engines. Apart from these operational assets, we are also engaged in power trading since June 2006.

Through our strategic approach for operational excellence, we aim to be present across multiple geographic locations, adopt energy-efficient technologies, diversify fuel sources, engage in prudent power off-take arrangements with a resolute commitment to sustainable business practices and strive for inclusive growth through organic and inorganic opportunities.

We lay great emphasis on quality, occupational health and safety, and environmental parameters through our production process. Our plants are certified to the following management systems:

- JSW Energy Limited-Vijayanagar (860 MW): ISO 9001-2015, ISO 14001-2015, OHSAS 18001-2015 and ISO 50001-2011

- JSW Energy Limited-Ratnagiri (1,200 MW): ISO 9001-2015, ISO 14001-2004, OHSAS 18001-2007 and ISO 50001-2011

- JSW Energy (Barmer) Limited (1,080 MW): ISO 9001-2015, ISO 14001-2015, OHSAS 18001-2007 and ISO 50001-2011

- JSW Hydro Energy Limited (1,300 MW): ISO 9001-2015, ISO 14001- 2015 and OHSAS 18001-2007

JSW Energy’s commitment towards minimising its environmental impact is reflected in its selection of coal. The Company’s prime focus is on the type that has a relatively less impact on the environment post combustion. Also, the coal rejects from the pulveriser are being reused in thermal power plant.

Moreover, we continually endeavour to optimise power consumption of equipment and drive process improvements. Some of the key initiatives undertaken during FY2019 are:

- Surge shaft structure was strengthened for arresting unwanted water leakage without depleting water conductor and without generation loss

- Annual maintenance in record time of 60 days for Karcham Wangtoo Hydro Electric Project (HEP)

- Heat pumps were installed to reduce the energy consumption for heating water

- Replaced CFL and Tungsten carbide bulbs with LED lights

- Insulation floor coating instead of insulating mat in front of LT panels

- In-house repairing of runner at eroded and damage portion of Karcham Wangtoo HEP

- Digitisation of various plant data on real-time basis

- Optimisation of powerhouse illumination load and Heating, Ventilation and Air Conditioning (HVAC) systems

- Reduction in auxiliary power consumption through optimisation of parameters of electrostatic precipitators

- Reduction in coal quantity and quality losses due to stringent monitoring

- Reduction in auxillary power consumption by installation of variable frequency drives across LT drives

- Reduction in auxillary consumption due to optimisation of running equipment (such as stoppage of one Cooling Water Pump (CWP), Auxiliary Cooling Water (ACW) and Boiler Feed Pump (BFP) during partial loading

Key Performance (Consolidated) Highlights and Outcomes

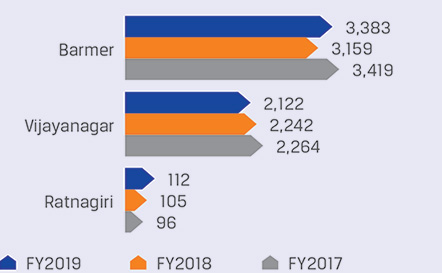

The consolidated net generation across plants was 22,088 MUs out of which 16,881 MUs was from thermal power plants, 4 MUs from solar power plants and 5,204 MUs from hydro power plants. The net generation this year improved owing to a high PLF achieved by the Ratnagiri plant. Conversely, we faced cost pressure due to rising imported coal prices, leading to rise in unit fuel cost.

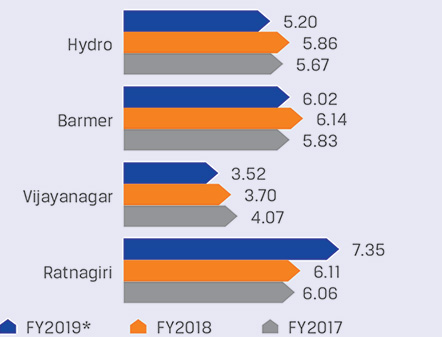

Plant-wise Net Generation (in BUs)

*Excluding 0.004 BUs from solar power plants.

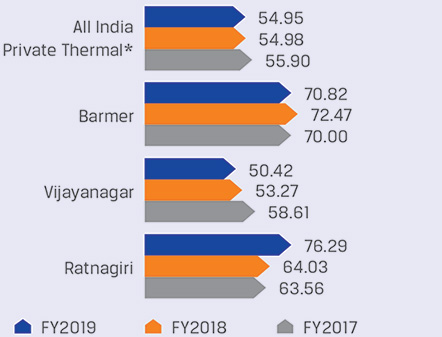

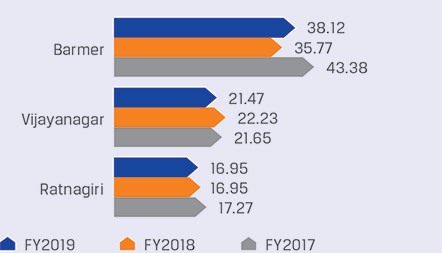

Plant-wise PLF (Thermal) (%)

*Source: CEA

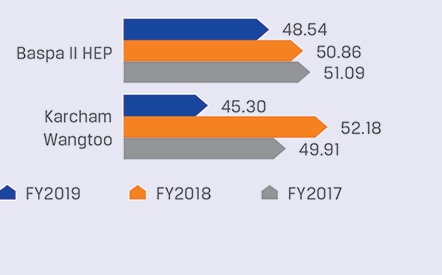

Plant-wise PLF (Hydro)

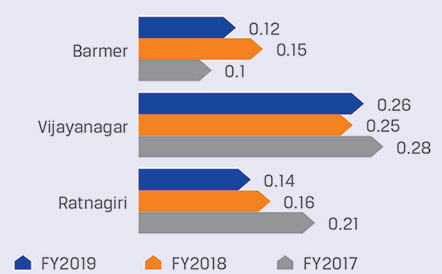

Special Coal Consumption (kg/kWh)

Water Consumption (m3/MU)

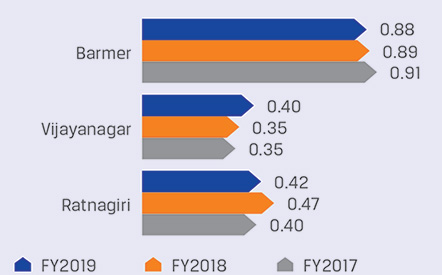

Special Oil Consumption (ml/kWh)

Special DM Water Consumption (m3/MU)

Fly Ash utilisation (%)

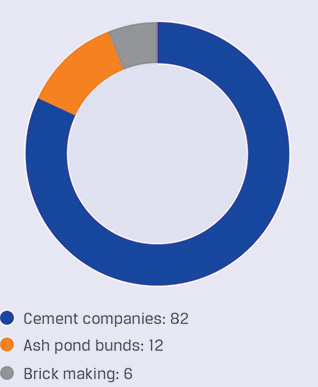

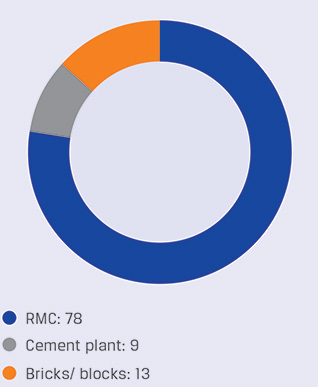

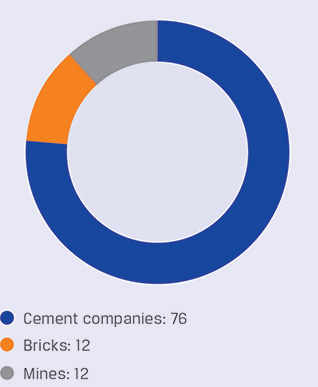

Fly Ash Utilisation Streams

Vijayanagar (JSWEL) (%)

Ratnagiri (JSWEL) (%)

Barmer (JSWEBL) (%)

Generation

Net Generation: 22,088 MUs with y-o-y increase of 1.25%

Percentage of the net generation through renewable source (hydro and solar power plants): 23.58%

The increase in net generation was a result of both higher long-term and short-term sales at Ratnagiri.

Plant Load Factor (PLF)

The Ratnagiri plant achieved a PLF of 76.29%, which is the highest PLF achieved by it in the last three years.

For Vijayanagar, Barmer and hydro power plants, the PLF decreased in FY2019 compared to FY2018.

Awards

JSW Energy’s continuous efforts towards managing efficient operations, enhancing social and economic benefits, minimising environmental impacts, and employing cutting-edge innovation was recognised through various awards. Some of them include:

JSWHEL - Porter Prize for leveraging unique activities

JSWHEL - Grow Care Award for outstanding achievement in safety management

JSWEBL - ET CSR Leadership Award under the Safe Drinking Water category under individual application; also selected for ‘100 Most Impactful CSR Leaders 2019’ at World CSR Day

Karcham Wangtoo Hydroelectric project - IEX Excellence Award under the category of 'Highest Electricity Volume Generator'

JSWEL - IPPA award for innovation in energy conservation by adoption of various innovative technologies and best operational practices

Power Purchase Agreements (PPAs)

Signed additional long-term PPAs of 250.50 MW during the year

Increase of long-term PPA proportion to 80.4% in overall offtake mix.

Trading Volume

Our total trading volume in FY2019 was 2,054 MUs compared to 3,546 MUs in the last reporting year.

Trading volume reduced on account of the Company’s undertaking direct sale of major quantum of power from its plants to customers. Also, JSWPTC, the power trading subsidiary of the Company, has facilitated its group company’s plants for supplying power directly to the utilities/industry.