Performance by Capitals

Natural Capitals

JSW Energy realises its responsibility towards conservation of natural resources for sustainable business growth. Being an energy-producing country, India’s dependency on coal is inevitable. We try to make every possible effort to ensure that we are utilising the nature’s limited resources in the most efficient manner. We keep a constant check on our waste production, and Greenhouse Gas (GHG) and Suspended Particulate Matter (SPM) emissions. While we are in compliance with the national and local guidelines for environmental conservation, we also undertake efforts such as tree plantation to ensure that our business is aligned to environmental sustainability as well.

Environmental Management

System

JSW Foundation, the CSR arm of

the JSW Group, is responsible for

strategising, executing and managing

the programmes specifically designed

for controlling our environmental

footprint and restoring natural capital.

Our contributions towards natural capital conservation were duly recognised during the year. We were awarded the CII Excellence in Energy Efficiency award for our Ratnagiri plant. The plant also got five-star rating for pollution control from Maharashtra Pollution Control Board (MPCB). We also received the IEX Excellence Award under the ‘Highest Electricity Volume Generator’ category for our Karcham Wangtoo Hydro Electric Project. Our Vijayanagar plant was recognised for reduction of startup oil consumption by the IPPA Award. The plant was also recognised for adopting innovative technology for energy conservation. JSWEBL got selected under the category of ‘Water Management Awards 2018’ in the Gold category. The plant also won the second prize in the category of ‘Energy Conservation’ by Rajasthan Renewable Energy Corporation Limited, Government of Rajasthan. Various CSR awards for betterment of environment has been bagged by our Barmer and Ratnagiri plants. The district administration of Ratnagiri and Barmer have appreciated the efforts put in by JSW for upliftment of environment and eradication of social evils prevalent in the society.

Life Cycle-based Approach for Environmental Impact Management

We assess the life cycle of our products to identify our key risks and opportunities at every stage of the production. It involves a multi-fold approach, which constitutes of the following steps:

Selection and sourcing of raw material

We select raw materials (viz. coal,

lignite, heavy fuel oil and light diesel

oil) from multiple geographies.

Our priority is to utilise coal that

has relatively lesser impact on the

environment, regardless of the

cost incurred.

Transportation of raw material

Imported coal utilised at Vijayanagar

and Ratnagiri is brought in by the

sea, and then transferred to the coal

stockyards via rail at Vijayanagar and

through direct coal conveying system

from the port to the plant premises

at Ratnagiri.

Electricity production

We try to mitigate the risks identified

as part of risk assessment procedure

for thermal power production at the

design stage itself. Only the equipment

having maximum efficiency is selected and standard operating procedures are

implemented.

Delivery to the customer

We take into consideration all

environmental guidelines while

fulfilling the energy requirement needs

of our customers.

All our plants at Ratnagiri, Vijayanagar, Barmer and Sholtu are certified with the various environmental and social management systems of ISO 9001- 2015, ISO 14001-2004, ISO 50001-2011 and OHSAS 18001-2015.

Promotion of Renewable Ways of Energy Production

We understand that the future of energy production is in renewable energy. We are thus aligning our business in the same direction and taking measures to promote the usage of renewable energy. At our Ratnagiri plant location, we have supported 12 biogas units in eight villages. The capacity of each unit is 2 m 3, which is sufficient for a family of five members. Cost of a unit is about `35,000, out of which `10,000 is supported by JSW. At JSWHEL Sholtu, we have installed 92 solar street lights in 12 Gram Panchayats of Direct Influence Zone. We have also commissioned a 1,000 kg capacity Solid Waste Management Unit at District Head Quarter Reckong Peo. We also undertook sapling plantation drive during the year and planted saplings such as Chilgoza, Cheer, Weeping Willow, Robinia, Apricot, Deodar, etc. with the support of local residents at JSWHEL Sholtu.

Measures to Reduce Power

Consumption

To improve our auxiliary power

consumption at our JSWEL plant,

we have undertaken the following

initiatives during the FY2019:

Condensate Extraction Pump (CEP)

The installation of VFD for Condensate

Extraction Pump (CEP) in 2014 led to

the reduction of power consumption

from 1,000 KWH to 850 KWH. In the

current financial year, an additional

saving was achieved by reducing the

setpoint which resulted in reduction of

power consumption by 227 KW.

Closed Cooling Wave (CCW)

We equipped our unit with three CCW

pumps (2W+1S) at full load condition.

By operating only one pump at 150

MW, we saved power of 165 KW.

Boiler Feed Pump (BFP)

As a part of APC reduction and

by analysing power consumption

whenever unit runs at 50% load, we

stopped one of the BFPs, which led to

the reduction of power consumption to

4,050 KW.

Cooling Water Pump (CWP)

To reduce the power consumption, we

stopped one of the CW pumps during

load resulting in 1,450 KW savings.

Coal Handling Plant (CHP)

With an objective to avoid idle running

of Bunker Ventilation System (BVS)

and to conserve energy, an alarm was

configured in Programmable Logic

Controller (PLC) to indicate that BVS is

running even though the conveyors

are not running. This will alert the

operator to take action and stop the system immediately whenever coal

is not fed. With this modification,

BVS power consumption reduced

drastically from 1,760 KWH/day to

650 KWH/day.

Our Environmental Performance

Maintaining a transparent relationship

with our stakeholders is crucial for us.

We, therefore, have been disclosing

our environmental and social

performance year after year. It not only

helps us maintain a strong relationship

with our stakeholders, but also help us

identify and monitor the KPIs for

our environmental performance year

after year.

Key Performance Highlights and Outcomes

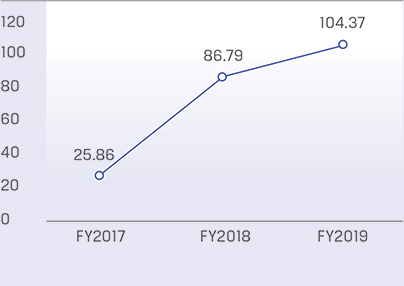

Energy Saving (MU)

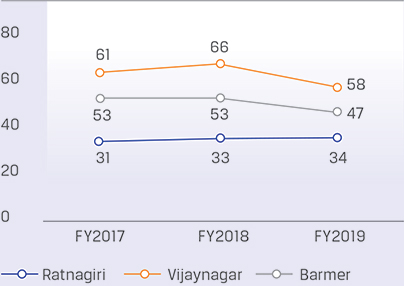

SPM (mg/NM3)

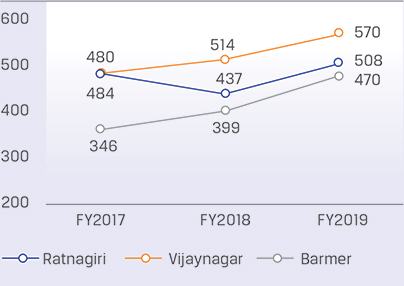

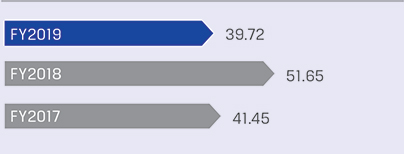

SOx (mg/NM3)

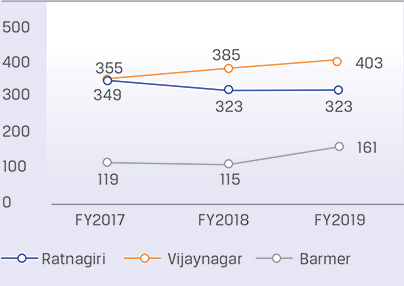

NOx (mg/NM3)

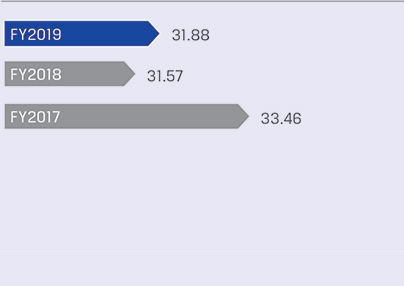

Specific GHG Emission (MTCO2e/MU)

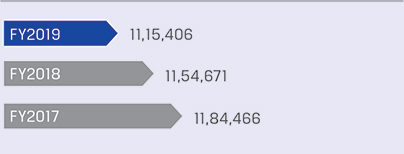

Water Consumption (million KL)

Waste generated at JSW Energy

Non-hazardous Waste (MT)

Hazardous Waste (MT)

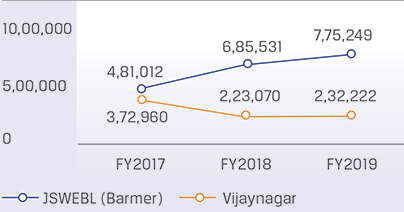

The following chart shows the quantum of wastewater that is treated in the last three years. However, our Ratnagiri plant uses a seawater cooling system, which results in zero consumption of natural river water. Therefore, the need to recycle is eliminated.

Waste Water Treated (KL)

Recycling

During FY2019, we recycled 24.1% and 6.7% of the total wastewater at our JSWEBL and Vijayanagar plants, respectively.

We installed an effluent recycling plant to recycle water at the Vijayanagar plant. Seawater cooling systems were installed at Ratnagiri, resulting in zero consumption and no recycling requirement.

Energy Savings

Our energy saving has been increasing for the last three years. This reporting year, we recorded a 20% increase in our auxiliary energy savings.

LED lighting and heat pumps were installed to save electricity.

Continuous performance monitoring of our electrical equipment such as DG sets are undertaken to access energy utilisation.

GHG Emissions

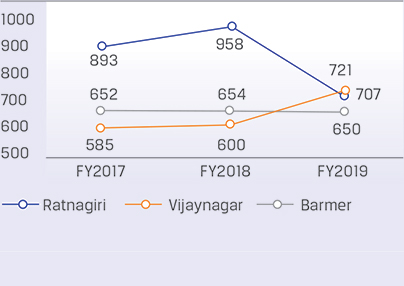

GHG emissions at our Ratnagiri plant reduced from 893 MTCO2e/MU in FY2017 to 707 MTCO2e/MU in FY2019 whereas it increased for Vijayanagar plant from 585 MTCO2e/MU in FY2017 to 721 MTCO2e/MU in FY2019. We have real-time data connectivity to pollution board servers at our Vijayanagar plant. The environmental performance of the Vijayanagar plant is also displayed at the main gate.

Environmental Initiatives

At our JSWHEL plant, we installed LED lighting and heat pumps to save energy. We encourage the usage of by-product gas from the steel plant in power boilers to displace coal at our Vijayanagar plant.

We organise awareness campaigns through activities such as Environment Day Celebration and essay competitions that provide innovative ideas related to energy conservation and environment protection.

Certifications

Internal and external audits for our plants’ performance are undertaken at least thrice a year.

Besides all our plants being certified to ISO 140001, ISO 9001 and OHSAS 18001, our thermal power plants are also ISO 50001:2011 certified.

Towards Clean Energy

JSWHEL is a hydro-based plant, which is a renewable source of energy production. Both projects at JSWHEL are based on the run-of-river hydro scheme, with no large pond and no emission of GHG. This helps in the sustainable development and the projects are registered under Clean Development Mechanism (CDM). The JSWHEL plant has also undertaken the initiative to cover the available land around the plant sites and open spaces within the premises with green belts, which lead to improved micro-climate conditions.